http://guil-liftingtowers.com/portfolio/tmd-570/

Modular Structure

This compact lift structure consists of five aluminium reinforced trapezium shaped trusses of 1500 mm (4′ 11.05″). It’s equipped with 3 truss strengthening braces that have aluminium couplers providing a high resistance to axial torsion (twisting along its axis) and to buckling.

The different truss sections are joined together with conical female couplers with spigots and safety R-springs, guaranteeing a perfect fit when truss sections are connected.

These stacking trusses, manufactured with extruded aluminium, are specially designed to be piled up, reducing storage space and making it easier to handle.

Lifting Process

This tower is assembled laying the truss sections on the floor so that, thanks to the hoist and its hinge design, the structure can be raised effortlessly into the working position (the hoist does all the work). Thanks to this feature a quick and easy raising and lowering of the structure is guaranteed.

Its versatile design allows it to be used both with a manual or electric hoist (NOT INCLUDED).

Top Section

The head piece is manufactured in aluminium, is detachable so that it can be stored on the base which facilitates its storage and transportation and contributes to its compact dimensions.

Its length of 1290 mm combined with the angle of the tower, provide the necessary curvature to the line array once raised on the tower.

It has been designed including an added rest element to be able to prop the head piece up on the ground during the assembly of the lifting tower, preventing it from suffering damages or deformations and is where the chain of the hoist goes through.

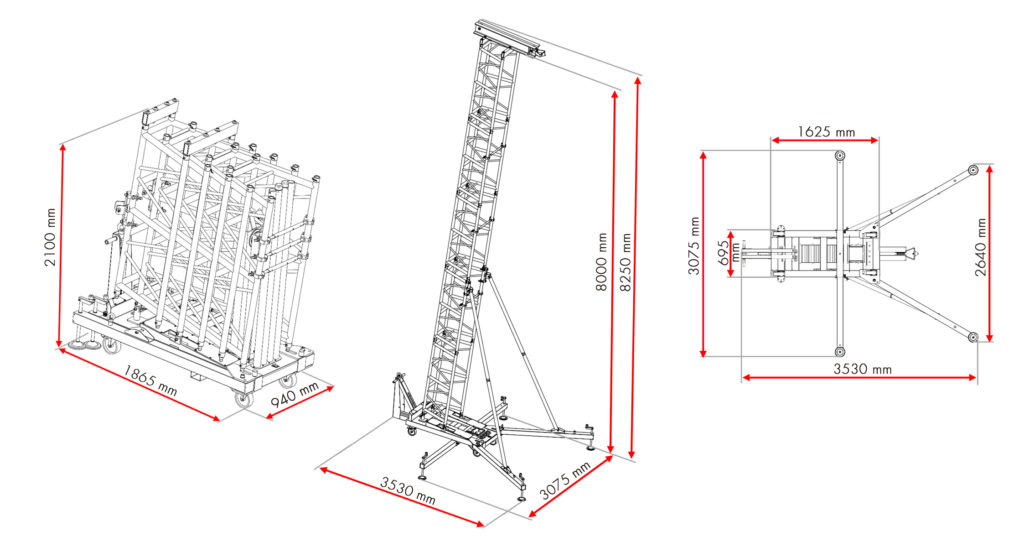

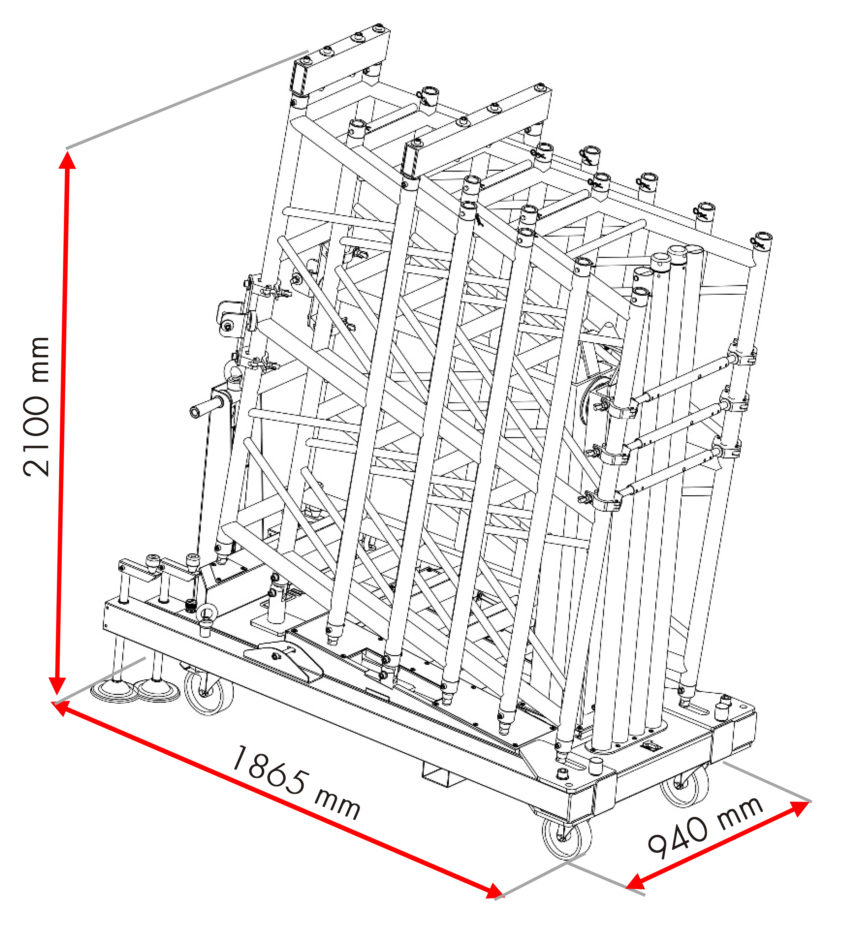

Base Section

Its compact base structure (940 x 1865 mm) is specially designed to store and transport all the components needed to assemble one complete Rigging Tower. As all the tower components are all together not only is the storage and transport space reduced but also the risk of losing components is reduced.

Made of steel, finished in textured black paint, it is provided with white Nylon protectors that help protect the tower from scratches and bumps.

The base features guarantee a perfect fit for all types of surfaces; with four removable stabiliser legs, equipped with levelling screw jacks and a spirit level to ensure a correct vertical adjustment.

Transporting the TMD-570 tower is easy, as its stability and movement are facilitated by means of its 150 mm wheels equipped with brakes and its maneuverability is improved with a handle installed on the base hoist support.

Thanks to its easy handling, convenient transport and quick assembly, the new Line Array PA Tower TMD-570 can be considered one of the most functional structures on the market.

Base Section

TMD-570 Rigging Tower has been manufactured with the most advanced equipment, carefully selecting the raw materials used and controlling the quality of all their components during their manufacturing process. Guaranteeing maximum safety and durability, complying with the light-weight, sturdiness and manoeuvrability requirements needed to lift audio equipment. These features, together with its special stacking design, makes this lifting structure the perfect complement for temporary assemblies (indoor and outdoor use) in which reduced size for storing and transporting and easy assembly are essential.

TMD-570 Rigging Tower complies with the requirements of safety according to the following Standards and Regulations:

- Directive 2006/42/CE on machinery

- DGUV Regulation 1

- DGUV Regulations 17 and 18

- DGUV Rule 115-002

- DIN EN 1999-1-1

- DIN 56950-1